STARLITE CREATORS Vol.1Skin beautify effect with original CNF dispersion drying technology?

Hello everybody, this is Akiko Tsujimoto, a member of the public relations at STARLITE. This time, I made my research about the "Cellulose nanofiber (CNF)", which is attracting attention as a next-generation material. Nano world research is very exciting! CNF, which is a carbon-neutral material derived from plants, has many features such as "light weight", "strong", "hard", and "highly transparent". It is extremely difficult to control CNF at the nano particle below the wavelength of light, and there is a high hurdle to achieve its widespread.

However, I am interested to hear that it is good for skin care, so I am excited to interview Mr. F.M., who is in charge of developing CNF's water-based dispersion and compounding technology!

Tell me now, what CNF is?

Of course! It is nano-sized material of cellulose fiber, which is the main component of plants. And as the name "nanofiber" suggests, it is a very fine fiber that is one millionth of a millimeter in size, but its strength is five times that of iron, its weight is one-fifth, and its coefficient of thermal expansion is one-fiftieth that of glass. These amazing characteristics are expected to be put to practical use, and development competition is taking place all over the world.

Five times stronger than iron! Why is it?

The point is that CNF is nanoscale. Since nanofiber has extremely large specific surface area and a large contact area with a medium such as resin, a high reinforcing effect can be exhibited with a small amount of addition. If CNF is dispersed on a scale of 1/10 or less of the visible light wavelength (400 to 800 nanometers), light scattering will be extremely small, and CNF will not be visible in natural light. In other words, it becomes a "transparent reinforcement", that can make a strong coating film without changing the color tone of the paint.

A high reinforcing effect can be exhibited with a small amount of addition・・・Is it still not ready for practical use?

Sure, even if we want to use this amazing material with a variety of products, the size of each CNF is 1 / 100,000 of the thickness of the hair, which is even smaller than the new coronavirus (100 nanometers). That makes it very difficult to break apart.

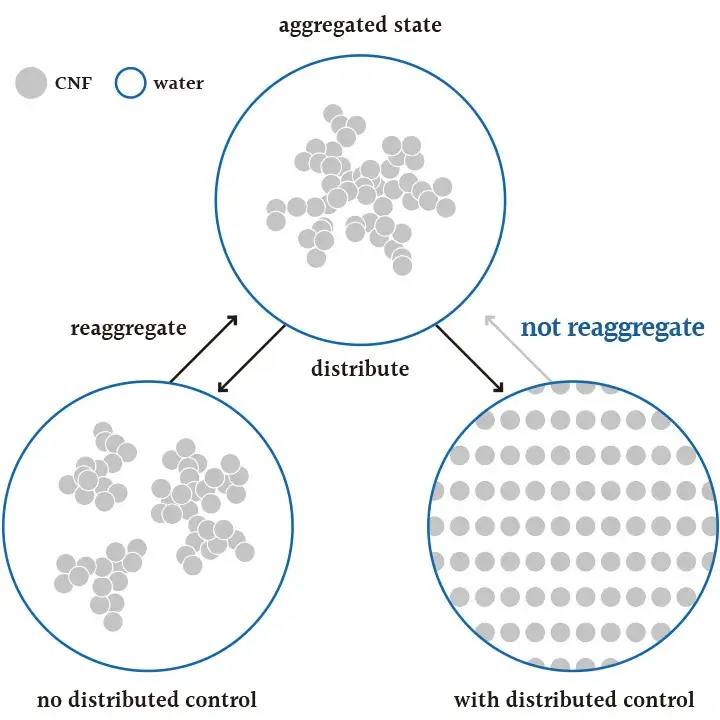

As it is so small, with even extremely small forces such as the Van der Waals force that attracts molecules each other, the bonding force between hydroxyl groups, and the interaction of the electric double layer due to the charging of the CNF surface, it will adhere and aggregate, and once reaggregated, they won’t easily fall apart. The true value of CNF is exhibited only when it is dispersed in the nano particle, so its dispersion control is very important.

Dispersion of nano-material・・・It's too small and the image is hard to understand

Don’t worry! STARLITE focused on dispersion in water systems and established a method for production of nano-dispersions of CNF. Although general CNF are already nano-sized to some extent, it is not sufficient to disperse into resins, so it is chemically modified to hydrophobize the hydroxyl groups of CNF, this requires each process to be tailored to each CNF from every supplier. STARLITE has developed a series of manufacturing processes that not only eliminate the need for that process, but also make it easier to mix with the resin.

It's getting harder ... Is it easy to compound with resin?

Yes! STARLITE has developed a manufacturing process specialized in dispersing CNF into solution, such as:

step.1

"Polymer dispersant" + "beadless dispersion method"- that can disperse water-based nano-dispersion of any CNF without pretreatment

step.2

"Unheated drying method"- to improve the mixing condition of nano-dispersed CNF into resin

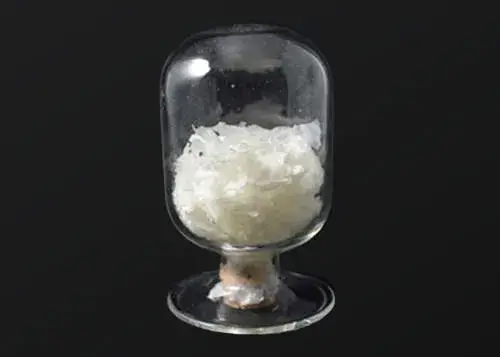

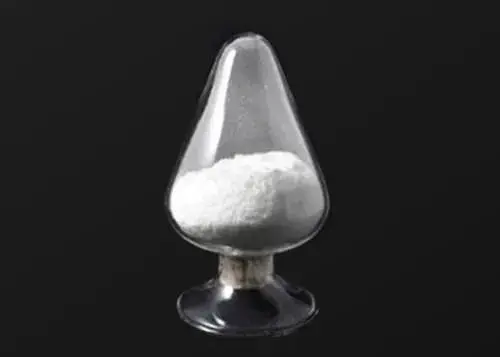

In case of using the normal dispersion method of nanoparticles, beads are collided with nanoparticles by rotation of a screw to and disperse them. However, the beads are easily damaged, and there have been such problems that require work to remove and sort the debris. STARLITE's beadless dispersion method maximizes the efficiency of polymeric dispersants and eliminates nano-dispersion and reaggregation, because of non-presence of beads. This eliminates the need to extract beads after processing, enabling a reduction in man-hours and realizing a mass production. In addition, when heated and dried for powdering, CNF becomes flakes like a thin skin in usual methods, making it difficult to mix with powder resin (Fig. A). However, by drying with a special method neither heated nor reduced pressure, CNF can be finished in a powder form as shown in Fig. B.

(Dry plate)

(Smooth powder)

We blended the CNF nano-dispersion produced by this manufacturing process, water-soluble resin having good compatibility with CNF, and a cross-linking agent for exhibiting functions such as high strength, heat resistance, and gas barrier properties. "Shiga process" is the name for dried and powder type, and "Lake Biwa process" for the aqueous solution type.

It means that the dispersion and drying are amazing. By the way, has the practical use for skin care been done?

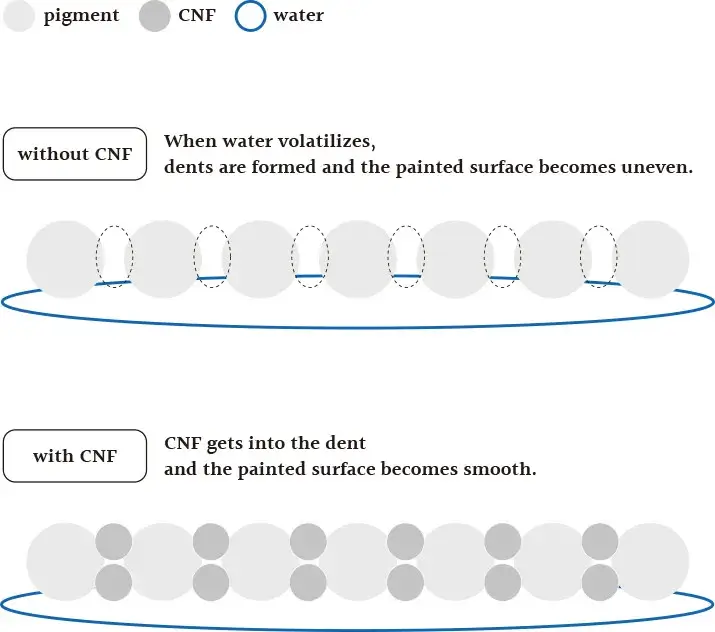

Hey, calm it down! It may seem that resin and cosmetics may seem different, but just the medium to be dispersed is different in front of nanotechnology, and the idea is the same. For example, cosmetics disperse pigments and ultraviolet protective powder particles in a water or oil base. If these particles are dispersed together with CNF in an ultra-uniform manner, color development and sunscreen effect will be improved.Furthermore, CNF assists evenly dispersion of pigments and nanoscale CNF fills the gaps between particles to improve not only the painting easiness but also to make the coated surface smoother.

Come Ooooon! I will definitely buy it so please hurry up.

Not only for cosmetics, CNF is attracting attention for paints and inks where pigment dispersion is important, and the pursuit of its dispersion technology is said to be an "eternal theme." As a front runner in CNF dispersion and combining technologies, I continue to challenge this theme. To realize the dream so that this technology will work into further applications!

Summary of interviews

- CNF has many excellent functions

- However, dispersion control is difficult and the hurdle is high for application.

- STARLITE develops technology to solve this problem

- This was CNF dispersion control and composite technology for water-based resins!

We hope to create new co-creation in partnership with customers.

Please feel free to contact us.

Based on our unique CNF dispersion / composite technology to water-based resins and joint development know-how so far, we can customize CNF + dispersant + various water-based resins according to your needs.Please feel free to contact us.