STARLITE CREATORS Vol.2Supporting food safety using Non-contact Type Static Bearing.

Bearings have played the role of "moving things easily" since the age of ancient Egypt. Along with its evolution, they have been also playing an active part in the new stage of "food safety" in modern times! I'm Akiko Tsujimoto, a member of the public relations at STARLITE. Let’s see the relationship between bearings and food. Now I’ll interview Mr.K.T.,who is in charge of development for hydrostatic bearing!

Hello! What are bearings used for?

Hi! I’m K.T.. "They are supporting rotating shafts". Bearings are important mechanical components because they support the load applied to the shafts and move the shafts smoothly and keep them at their right position.

It looks like a simple cylinder ...

Oops, it’s not a simple cylinder but It’s shape reduces energy loss and rotates more smoothly to support quiet and comfortable rotating movement. If there were no bearings in this world, we might still have carried heavy things with great force and high cost. “No bearings, no our lives”. Bearings are indispensable components in the compressors or motors for vehicles or home appliances.

Wow...! It sounds very important indeed. Since when have they been used in Japan?

The first bearings made in Japan are said to be the one manufactured at the request of the Navy in 1916. It was around the time that a Japanese company, which is now leading the bearing industry, was founded, and they were developing metal bearings. Since then, the performance of machinery has been improved dramatically with the development of industry, and various types of bearings have been created to meet requirements. STALITE has been supplying plastic bearings for about 80 years since 1941.

Are there any differences between metal and plastic, and what kind of applications do we have?

Metal bearings are commonly used, but they must always be lubricated to protect the sliding and rolling interfaces. When the lubricating oil reaches temperatures as high as 150℃, the lubricating performance decreases significantly and the lubricating oil itself deteriorates.

Therefore, plastic bearings made of S-Bear ※1, which has excellent self-lubricating properties, are indispensable under high-temperature conditions. the steel rolling mills producing 1,000℃ iron, which is burning red, are made of STARLITE BAKES ※2. It applies to use in environments where corrosion such as rusting is likely to occur.

- S-Bear is an original sliding material that can be injection molded. It is mainly used in electrical equipment and sliding parts and gears for automobile applications.

- BAKES is a generic name of products based on phenolic resin, and is highly resistant to heat and abrasion that does not damage the mating material.

I was thinking metal is the strongest! but the plastic is also amazing ...!

It was worth talking so far. I'm happy to talk about bearings like this. Almost all of the plastic bearings are "sliding bearings," and the movement of the bearings is supported by the inner surface of the bearings. Compared to roll bearings, they have excellent load resistance, less likely to generate vibrations, have a simple structure, and can be compact and save space.

However, if these sliding bearings do not have an appropriate sliding function and appropriate bearing peripheral design, abnormal bearing wear, shaft shake, and shaft damage will occur. For example, a cooking hand mixer rotates at its tip part at high speed to whisk fresh cream, but if its shaft is shaken, the fresh cream will scatter around it.

if bearings are damaged or worn, foreign matter such as wear powder will mix in fresh cream. We’ll have way too many other things to worry about besides making a delicious cake.

I hope I could have a safe mixer that doesn't scatter cream...!

Could you? It's just a single bearing part that can shake customer trust. It is usual that larger hand mixers are used in the fresh cream factory, but it is very difficult if a problem occurs there. The foods we eat are not just delicious, but also important to be able to eat safely. Needless to say, that foreign matter should not be mixed in. Maintenance of the manufacturing line is one of the measures to prevent foreign matter from entering. Shaft maintenance involves the steps of disassembly → cleaning → installation. However, the larger the manufacturing machinery is, the more difficult it is to "pull out and remove the shaft from the bearing" and "clean off rust and deteriorated lubricating oil".

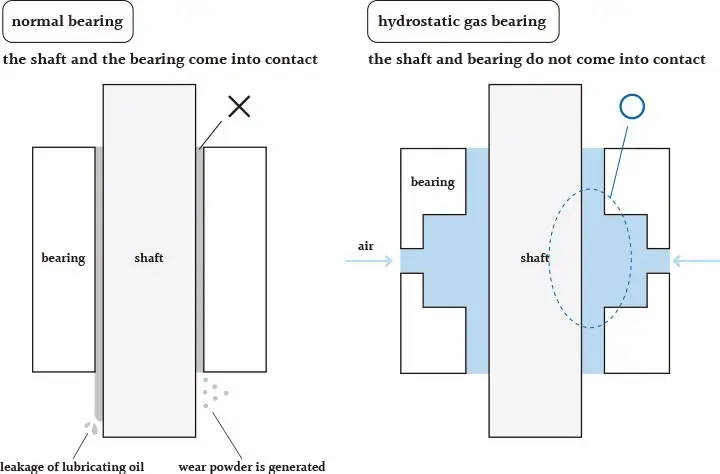

This is an absolutely associated challenge as long as the shaft and bearing are in contact with each other at the face. STARLITE's Non-contact Type Static Bearings were born out of this idea that bearings do not have to come into contact with shafts.

Eliminate contacts if you eliminate wear

That’s right! hydrostatic bearing supports rotation by floating the shaft with compressed gas, so frictional resistance is extremely small between the shaft and bearing, reducing the generation of worn scrap. It also reduces the frequency of replacement because the shaft does not damage. Then, since there is no need for lubricating oil or grease, it is also possible to achieve high cleanliness. In addition, since the material of the bearing is made of plastic parts, it is resistant to corrosion and does not generate rust. As described above, with the introduction of hydrostatic bearing, one of many issues in food manufacturing can be cleared. If the production line is clean and the cleanliness is remarkably high, maintenance work such as cleaning work will be drastically reduced, and this will also be useful in terms of work safety.

Non-contact Type Static Bearing Achieves 30,000 rotations!

Mr. Bearing protects food safety!

Yes! Contamination of foreign matter will be a bad influence not only on the taste and quality of foods. For example, for those with allergies, even a very small amount of foreign matter, can be fatal. I think I will faint just thinking if that happens to my family. I would like to expand the range of hydrostatic bearing that resolve such concerns to the world. For a world where safe, reliable, and delicious foods are common for a long time.

Summary of interviews

- Bearings are indispensable for our lives.

- Plastic bearings such as S-Bear and BAKES demonstrate performance that surpasses metal bearings.

- Non-contact Type Static Bearing can realize a clean production environment.

We hope to create new co-creation in partnership with customers.

Please feel free to contact us.

STARLITE's unique Non-contact Type Static Bearing not only reduces the worn scrap and rust from the bearings of the manufacturing machine, but also achieves high cleanliness of the manufacturing machine and reduction of maintenance work by reducing the frequency of replacement or oilless and greaseless. We respond to problem solving in food production lines. Please feel free to contact us.