STARLITE CREATORS Vol.6Protection by functional coating “BARIAS”

Hi! This is Tsujimoto from Public Relations. I recently took the plunge and coated the floor in my house. The coating protects the floor for more than five years. This means that I don’t need to bother with waxing every six months! It’s great!! I come to think…Starlite has the “BARIAS ” coating technology. What is it actually protecting?! Let’s interview two engineers, SH and KM!

It’s been a while! Please can you tell me about BARIAS?

SH:You are full of energy as always! :)

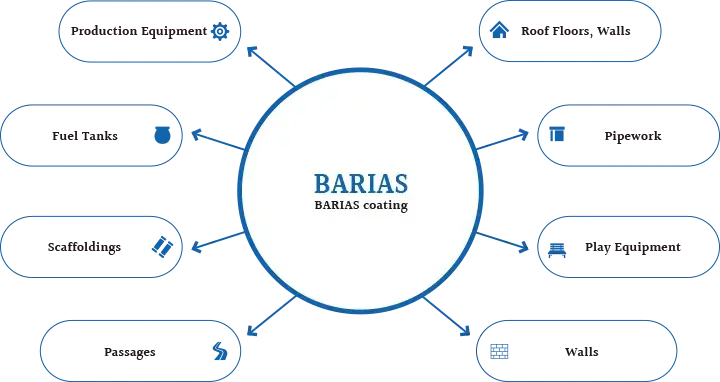

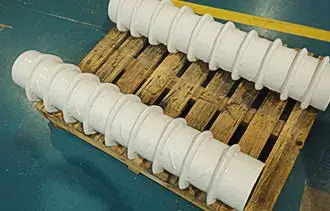

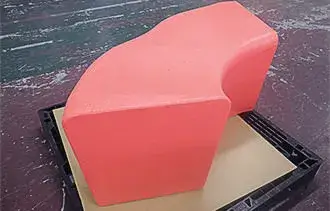

BARIAS is a coating technology based on polyurea. Originally, polyurea has excellent impact-absorbing performance compared with urethane, etc. and it could prevent walls from collapsing when exposed to a blast. It is also waterproof, wear-resistance and non-adhesive. The best feature is that BARIAS can be applied to complex shapes or to existing equipment.

How did you start to develop BARIAS?

SH:We started to develop it when we were approached by a customer. They wanted to prevent water leak from the tanks of large vessels. We conducted many trials using polyethylene and epoxy resin, but we could not stop the water leaking through the joints.

When we faced the problem, one of senior colleagues advised us “if you are concerned about the joints, just eliminate them.” That was when we tested the polyurea coating. It was strong and I knew it would work.

KM:Polyurea coatings have been available for a long time, but their application has been for specific purposes such as disaster prevention and large scale facilities such as civil engineering and construction. What we turned our attention was industrial and production equipment usages.

Was the application-based development important?

SH:Yes, but it was not easy. Our test data such as JIS tensile strength was not enough to answer questions such as compatibility with customer’s objects or the effect of application conditions. We went around Japan and made various proposals, but as expected, no one was interested. We knew we could not continue like this. We spent the rest of our time collecting data for customers.

We made our own hypotheses, applied coating and conducted tests every day. It did not matter if the results were good or bad. As long as we could see the results, we were one step ahead. When I think about it now, I was ridiculously positive and my desire to succeed was very strong. It did not matter if I was an engineer, I was not a salesperson, etc. “Do everything we can. Get it done no matter what.” We forgot about the time. It took us five years before we managed to get enough data and got a customer who said “Let’s try it.”

What kind of applications does BARIAS have now?

KM:We are improving durability of production equipment and reduce maintenance hours. In Japan, new investments for factory equipment have been restrained, and existing facilities are becoming increasingly outdated. BARIAS can be sprayed and repair damaged areas, without having to replace the entire equipment. After that, equipment can be used for longer. It is easy to maintain too.

SH:Plus, it is not just about repairing. The best thing about BARIAS is that the coating adds a new function.

How much are you going to make me happy?!

KM:Using make-up as an example, the purpose is not only “to cover up areas of concern” but also to protect the skin from UV, keep radiance, and prevent wrinkles from forming, and so on. It gives additional happiness. BARIAS coating does not just “cover up damaged areas,” it also has the added benefits of preventing staining, improving durability and making it less flammable.

It can provide future-proof cares as well!

SH:Equipment is something you use all the time. If I could maintain a factory, “I would want to make sure it was always clean and working at 100% capacity”. I am sure it is the same for customers.

Of course, how to keep in good condition all the time depends on the environment in which it is used. If it is outdoors, we want to make sure it does not get ravaged by UV or rust. If it is in a high-traffic area, we want to make sure it does not wear out and get peeled. I try to draw a mental picture of customers’ manufacturing sites. As soon as I think “don’t they need something like this,” I go and check out their sites.

Too active! :) Can you please tell me about a BARIAS product you have a special attachment to?

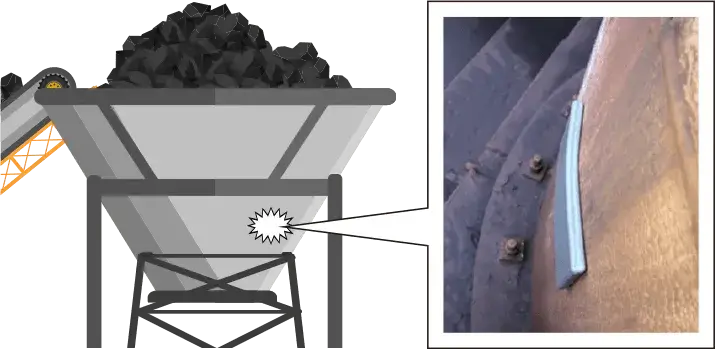

SH:After all, the first project we obtained was unforgettable. BARIAS’s resistance to wear, adhesion, corrosion and impact was recognised, reducing the impact fracturing and sticking that occurs when feeding raw materials into the hopper used to blend coke and other raw materials at the steelworks. It also reduces repair and cleaning costs significantly. We received a certificate of appreciation from the customer. I was really pleased.

KM:I remember the patch for the temporary repair of the raw material feed hopper. The patch is like a plate made of BARIAS and it covers up the repaired area. The patch adheres very well to the hopper and is very durable, so it can be used repeatedly and is very economical.

After many consultations with the customer, design changes and sample evaluations, we were able to complete the project. It was the most difficult project, but when the customer said "It's so easy to use!” all the hard work was forgotten!

It prevents raw materials from falling through the damaged area!

Raw Material Hopper at Steelwork

BARIAS Patch for repair

Starlite has more than 60 years of experience in production equipment, but with BARIAS, we will be able to do even more!

KM:Now that the data accumulated by SH and his colleagues has clarified BARIAS’s strengths and weaknesses. It is now up to us to identify the places where it is needed and make concrete proposals that are more and more feasible. We would like to develop products that make use of the new BARIAS functions, such as weight saving, improved durability and super water-repellent property, which allows water droplets to roll off the surface in a ball. We will also consider automation and standardisation in order to improve quality and speed up the process.

SH:We are living in an age of divided roles, but I would like KM and the younger generation to have more experiences with the “try everything” spirit. In order to come up with more concrete ideas, knowing only one part of the process is not enough.

I think the best engineers are the ones who are able to give shape to their ideas when coming up with an idea. That’s why I keep pestering young people with questions and requests even if they find it annoying :)

Interview Summary

SH is older than my father, but he is so energetic! We talked endlessly about the five years it took to receive the order, the prospects of expanding businesses with KM (This part is omitted in the article with the utmost reluctance). I was really thrilled. It is the Starlite creators who continue to challenge themselves with curiosity regardless of their age.

If you require more information on BARIAS, please contact from below.

BARIAS series is a solventless and tough coating. Its reinforcement and protection effects such as impact-resistance, wear-resistance improve the durability, safety and maintainability of facilities. Please feel free to contact us.