Brandnew Info - 22/07/2022Starlite develops a brake friction material made from inedible biomass-based resin and received the 72nd Industrial Technology Award from the Osaka Industrial Research Association.

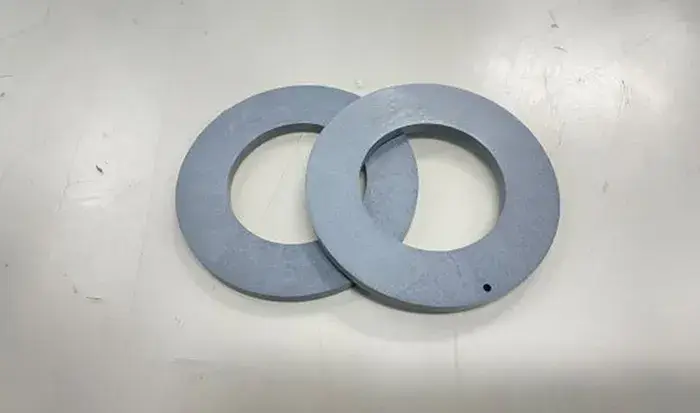

Starlite Co., Ltd has developed a new brake friction material (x2101) made from inedible biomass-based resin for collaborative robots.

brake friction material (x2101)

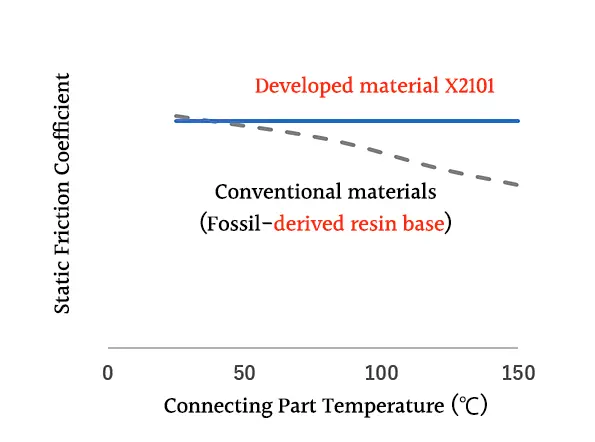

The main feature of the material is that the change in friction and wear from temperature change is smaller than the conventional friction materials made from fossil-resource-based resin. As a result, quiet and stable holding and braking forces can be expected. In the future, we will apply the new material for spring-actuated brakes, controlling the holding and emergency braking of collaborative robots, for which there is an increasing need from large-scale factories to small-scale restaurants.

Until now, thermosetting resin-based friction materials have been used in brakes because changes in its property due to heat is smaller, however, “heat generation” from the holding of an object and emergency braking has had a significant impact on braking performance.

The newly developed material x2101 shows almost no change in static friction performance between 25 degrees and 150 degrees, while its wear resistance characteristics, which indicate durability performance, are twice that of conventional materials (fossil-derived resin base) (see Graph1). Thus, the new material significantly outperforms the previous performance in a high-temperature range, which is a challenge for brake friction materials, and can provide stable holding and braking force under any operating conditions.

Starlite received the 72nd Industrial Technology Award for this technology from the Osaka Industrial Research Association in May 2022.

<Characteristics of Developed Material x2101 (friction material for brakes)>

- Made from inedible biomass-based resin*1

- Stable friction performance in a wide range of temperature

- Quiet and stable holding and braking force. Longer service life due to less wear compared to conventional materials

- Thermoplastic resin-based and is suitable for injection molding

*1: biomass plastic content of 25% or more.

Inquiry and Contact : https://starlite.co.jp/en/contact/

Recent Brandnew

- 29/10/2025Starlite's resin gears are used in the family robot, LOVOT.

- 16/09/2025Starlite provided technical cooperation for TJM Design's Sekhmet.

- 01/09/2025Playground equipment coated with BARIAS was installed at Shiroppa, an all-weather playground, in Fukui City Central Park.

- 16/05/2025The durability of resin gears has improved significantly with our new gear material (X2406).