On Your Side Vol.3OSHIKIRI

MACHINERY

OSHIKIRI × ALP Rollers for bread making and confectionery machineThe "mutual contribution" born through " Doing thoroughly " with OSHIKIRI MACHINERY helps to boost the commitment to food texture to lead to the society with full of smiles.

STARLITE does not spare efforts to verify and improve its products in order to achieve the required quality level. OSHIKIRI MACHINERY's bread making and confectionery machines pursue optimum "non-sticking and stable" function for the food texture and sanitation. Through shared understanding of engineers at both companies and repeated try and error to obtain completely new ALP Rollers for bread making and confectionery machines, have been developed and are functioning at the various important sites.

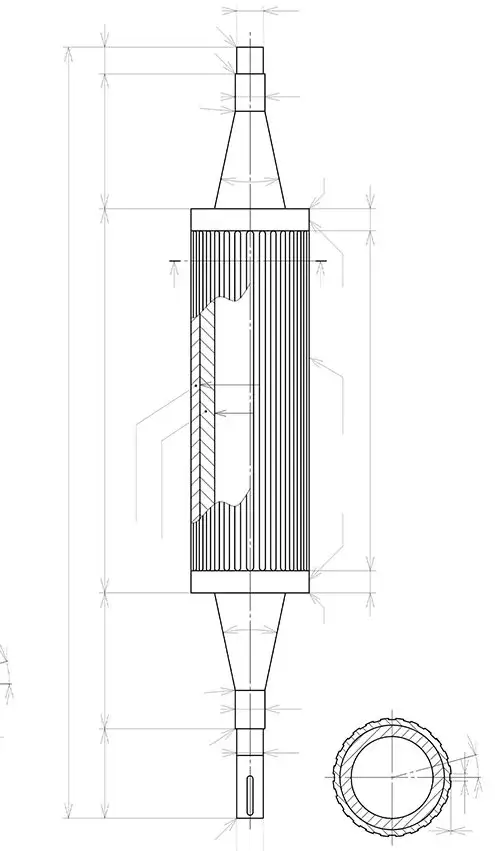

ALP Rollers for bread making and confectionery machine

Providing excellent non-sticking performance to cope with food, chemicals, oils and organic solvents, they show excellent durability and antifouling properties that are effective in food sanitary environments.

The lengthy long scaled molding method, which is paticular about self-lubrications and non-sticking performance enable degassing in the food manufacturing process, also leads to the pursuit of deliciousness.

On Your Side Vol.3 OSHIKIRI × STARLITEThe interview series to customers

OSHIKIRI Mr. Wada:"STARLITE is stable in quality and its supply system is very reliable."

STARLITE Omae:Thank you for your long patronage of the ALP Rollers for bread making and confectionery. OSHIKIRI has been developing business for fresh meats, marine products, chemicals, and other fields and has received rewards the food-related awards both domestically and internationally in the bakery and confectionery industries We are very proud that our products are being used as part of your machine.

OSHIKIRI Mr. Wada:ALP Rollers are indispensable for the core parts of our bread making and confectionery machinery, so STARLITE’s supply system with stable quality for long years is very reliable. We have developed technologies that link "people” and “food" around the world. When I go abroad, mainly Asia and the Middle East, I realize that there are still persistent demands for delicious bread in enough volume. Food safety plays a significant role in realizing a sustainable growth in society, and we believe that the pursuit of deliciousness as well as food safety will become increasingly important in the future.

STARLITE Omae:I feel that increasing demand for food safety is a natural trend toward the realization of a sustainable society. As the ALP Rollers directly touches bread dough, we have a particularly strong awareness of hygiene management even at the manufacturing stage.

OSHIKIRI Mr. Wada:Because ALP Rollers are made of non-sticking materials, they can thinly roll out bread dough. They help improving the bread quality dramatically. In addition, as they minimize maintenance work such as cleaning, man-hours are decreased and safety is improved. Therefore, they get a high reputation from our customers who actually use our machinery.

STARLITE Omae:"The design capable of controlling the bubbles and focusing on durability."

STARLITE Omae:I’m so happy to hear that ALP Rollers discharge and control the carbon dioxide gas produced from yeast in bread dough. We believe that finely and evenly control of bubbles is necessary to make “delicious bread” with good texture such as fluffy and sticky when chewing. It must not be happened to have unevenly eliminated bubbles due to warping or deflection of ALP Rollers, therefore the design and manufacture focusing on durability that do not deform, deteriorate, and wear out are required.

OSHIKIRI Mr. Wada:Before we use the current ALP Rollers, we had difficulty with degassing of very sticky bread dough. We grappled with the knotty problem “how thin can bread dough be rolled out” in the manufacturing process. It was the start of a three-legged race development with STARLITE. We repeated trial and error on a number of issues and repeated prototypes. When we were able to satisfy the evaluation test for the final actual machine, I was so happy to share the joy of this achievement.

STARLITE Omae:When Mr. Wada consulted us, I thought that it would be possible to solve the problem if I could use ALP Roller for the lengthy molding Rollers. However, it was a challenge to manufacture the lengthy molding ALP Rollers with stable quality. That was very tough to work to resolve a number of issues, such as material development, shape design, and production technology. Though no good result was obtained and I had been spending depressing days, but I still remember vividly that the scene I saw that parents with little kid enjoyably choosing bread in a shop strengthen the sense of mission. Looking back now, I've had a lot of experiences, and ALP Rollers are my pride.

OSHIKIRI Mr. Wada:It's a wonderful episode! I want to spread the smile and happiness of that scene to more people, and I feel that is my mission. I am confident sharing of each value makes it possible to create good things. By the way, Mr. Omae. Would you like to try a piece of bread? Can you feel that there is no unevenness of bubbles?

STARLITE Omae:Okay! I will try it. The flavor spreads evenly and it is really tasty! I'm glad that the experience that has continued to innovate will bear fruit, and that it will eventually become commonplace, and that society will move toward a slightly better direction. I'm impressed by eating bread. We STARLITE will continue to make proposals that exceed expectations with our tribology technology. Please contact us at any time. We thank you so much for today.