On Your Side Vol.4KYUSHU

UNIVERSITY

HYDROGENIUS

KYUSHU UNIVERSITY HYDROGENIUS × ALP, the composite material grade, for ultra-high pressure hydrogen compressor sealingThe “functions” created through “discoveries” with HYDROGENIUS (KYUSHU UNIVERSITY Research Center for Hydrogen Industrial Use and Storage) have elevated the possibilities of a hydrogen energy society, and that has led to the practical application of hydrogen stations.

STARLITE’s original material, ALP, is making great strides in the field of ultra-high pressure hydrogen compressor sealing through our joint research with HYDROGENIUS. Toward the realization of a future hydrogen energy society, our joint research is progressing to further advance the “durability and retention” of the material, which has already been put into practical use in hydrogen stations. We will be sharing the secret story behind the development of “the composite material grade, ALP, for ultra-high pressure hydrogen compressor sealing.”

ALP, the composite material grade, for ultra-high pressure hydrogen compressor sealing

The ALP is applied as a piston ring in ultra-high pressure hydrogen compressors at hydrogen stations.

Based on the knowledge accumulated through joint research with specialized research institutes, it is designed to be highly durable with little wear and tear even in a hydrogen atmosphere of 85MPa.

On Your Side Vol.4 KYUSHU UNIVERSITY HYDROGENIUS × STARLITEThe interview series to customers

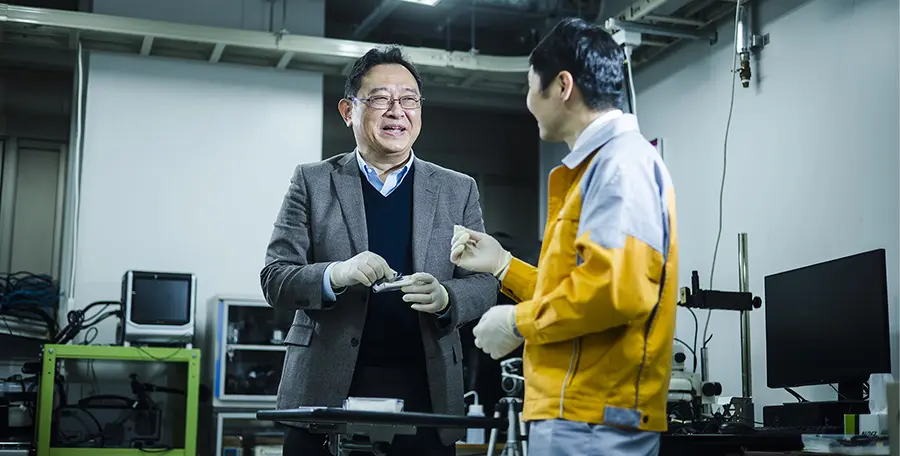

KYUSHU UNIVERSITY:Professor Sawae“Sharing ambition is essential for a joint research”

STARLITE:UejimaThank you very much for allocating your precious time for the interview on the joint research with you. Looking back, I think it has been about 15 years since we started joint research with KYUSHU UNIVERSITY. The knowledge gained through the joint research has become the foundation for STARLITE’s material development, which has led to solid results such as newly developed piston rings, the introduction of highly durable rings for compressors, and feedback to our customers. I would like to thank you and your team once again.

Lately, I started seeing hydrogen fuel cell vehicles and hydrogen stations on the streets. I feel that the hydrogen energy society is spreading slowly but surely. Every time I see this, I realize our research is taking shape and I am glad I have continued my research.

KYUSHU UNIVERSITY:Professor SawaeI was also looking forward to this interview. In foundational research, we do not have many opportunities to feel that we are contributing to the “creation of a better society” because we do not make products for society directly. However, we hear episodes like the one you told me about in joint research with corporates, which makes us more enthusiastic about our research.

I remember that we started our joint research around the time “HYDROGENIUS” was established. Fukuoka Prefecture launched the “Fukuoka Strategy Conference for Hydrogen Energy” and KYUSHU UNIVERSITY joined as a member. At that time, I remember feeling that it was really meaningful to launch an initiative in Fukuoka for the practical application of hydrogen energy, which is expected to be the next-generation clean energy.

STARLITE:Uejima“Academic knowledge and insights are indispensable for functional material developments”

STARLITE:UejimaThis research is also encouraging for me to develop functional materials. Thank you very much. I am deeply moved by the fact that advanced scientific research on clean energy is being conducted in Fukuoka, for there are many areas in Fukuoka that were once flourished as coal mining towns.

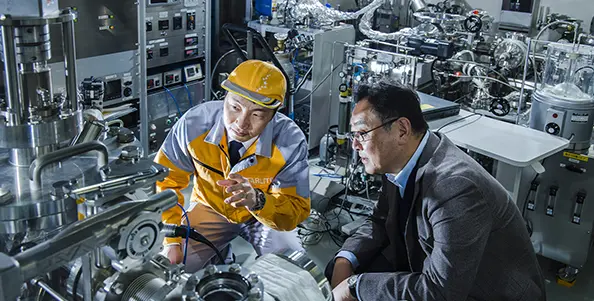

HYDROGENIUS conducts research on hydrogen and technologies and materials that are essential for the safe and efficient use of hydrogen. In particular, HYDROGENIUS has capabilities to provide time-consuming testing and data analysis, utilizing experimental technologies using high pressure and high purity hydrogen gas, evaluation technologies for material strength, friction, and wear, and advanced analytical technologies. Your perspectives and advice on the test results are very attractive for STARLITE, which needs academic knowledge outside the company.

KYUSHU UNIVERSITY: Professor SawaeHydrogen is attracting attention as the “energy carrier” of the future. Various energy is transformed into hydrogen, which is carried to where and when it is needed. The next question is how to transport the transformed hydrogen. Currently, the methods being considered include compressing hydrogen gas into high pressure gas or transporting it as a liquid by cooling or absorbing it into toluene, etc. As society adopts new energy production methods such as solar power and biomass, the possibilities of hydrogen as an energy carrier will expand further along with it.

“Fuel cell vehicles (FCVs)” run on hydrogen are also drawing attention as clean vehicles, however, in order to commercialize it, it is necessary to establish infrastructure to safely “store,” “transport,” and “supply” hydrogen required for full-cells. “Hydrogen stations” are a typical example of such infrastructure, and “hydrogen atmosphere (environment filled with hydrogen) tribology” technology is indispensable for compressing hydrogen at ultra-high pressure.

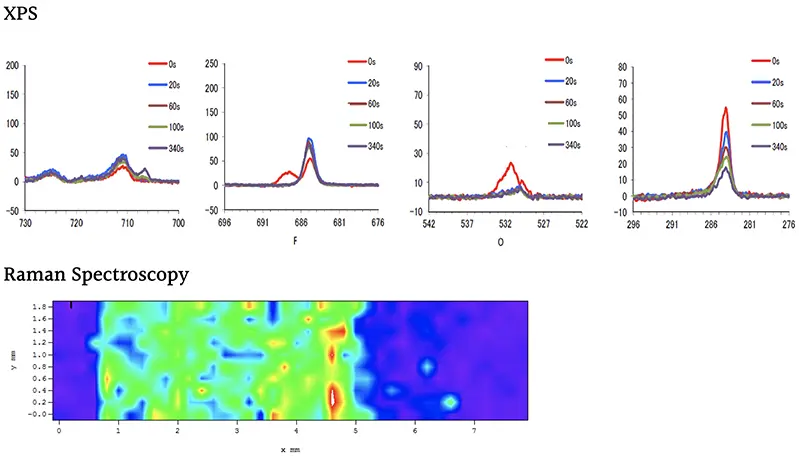

What happens when high polymeric base material slides on the metal surface in a hydrogen atmosphere? For example, understanding the formation of reactive products to the mating metal surface, changes in chemical and mechanical properties, and how each element is related to friction and wear will lead to significant progress in ultra-high pressure sealing technologies.

STARLITE:UejimaIt is the subject of our joint research. The method of boosting the pressure of hydrogen gas up to 70MPa for “FCVs” is now in the practical stage. On the other hand, the hydrogen infrastructure (gas station) supplying high pressure hydrogen gas to fuel cell cars must “safely” store and transport hydrogen gas that has been pressurized to an even higher pressure of 80 to 100 MPa. I feel that we still do not have enough knowledge on how mechanical parts such as bearings and seals used in the hydrogen station slide in high pressure and high purity hydrogen gas.

A technique to seal hydrogen that has been boosted to 100MPa has already existed as a prototype more than 20 years ago, but it did not achieve sufficient durability for long-term practical use, and “100MPa” is still an unknown area.

KYUSHU UNIVERSITY:Professor Sawae“Establish safety design guidelines for hydrogen-based mechanical systems”

KYUSHU UNIVERSITY:Professor SawaeYes. Hydrogen is not inert to the material surface, so additional data collection and verifications of friction and wear mechanisms in the high pressure gas atmosphere are necessary. The resin piston ring of the compressor, attached to the piston area which compresses gas, slides on the metal surface in high pressure and high purity hydrogen gas. In design, understanding friction and wear behavior in the gas atmosphere is greatly related to efficiency and service life.

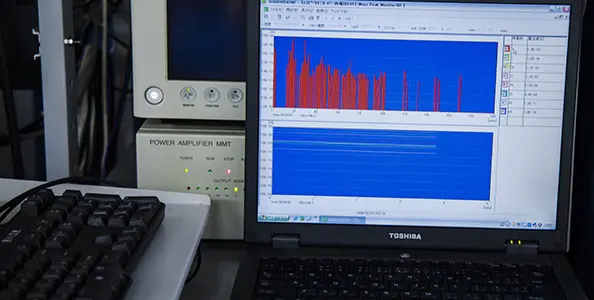

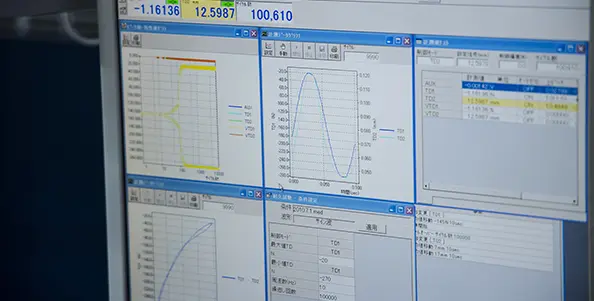

In addition to experiments using high pressure gas exposure samples, we are also preparing experimental facilities to measure the friction and wear characteristics of materials in the gas atmosphere “on-the-spot.” Through these experimental facilities, the development of a database on the material tribology properties in the gas atmosphere will lead to the establishment of safety design guidelines for hydrogen-based mechanical systems including FCVs.

STARLITE:UejimaDiscussions we had based on the friction and wear data collected from the “Advanced Atmosphere controlled Friction Tester,” an experimental facility dedicated to this hydrogen research as well as the results of surface analysis by XPS form the foundation for material development.

KYUSHU UNIVERSITY:Professor SawaeI must say that discussions with you are interesting because the phenomena that occur in the field are the subjects we talk about, and those include insights that cannot be gained through research alone. I feel that the ALP is so lovable because it lies between real voices from the field and experimental data and supports the expansion of hydrogen society :)

When I was with students the other day, we talked about “How much force 100Mpa is.” As an example, the bottom of the “Mariana Trench,” the deepest trench on Earth, is 10,000 meters deep, and its water pressure is 1000 atmosphere = approximately 100MPa. I said that is as if a 1,000kg (1 ton) weight is placed on a 1 square centimeter (approximately the size of a pinky fingernail) from 360-degree directions, top, bottom, left, and right. The students said it was difficult to imagine…

STARLITE:Uejima“We want to contribute to the realization of a hydrogen society with our tribology technologies”

STARLITE:UejimaI understand your love for materials! :) A 1-ton weight on a pinky fingernail from the top, bottom, left, and right… I can only imagine how painful it would be :) Maybe one day we will be able to dive into the Mariana Trench in a resin deep-sea probe with the technology to seal hydrogen boosted up to 100MPa. :)

The blue sea and green forests you can see from the windows of this research center. Can we leave this scenery to people hundreds and thousands of years from now….? The key is to realize a hydrogen society. I think that our generation still has a lot to shoulder.

KYUSHU UNIVERSITY:Professor SawaeFukuoka prefecture is comprehensively promoting the development and dissemination of hydrogen energy and undertaking social demonstrations to realize a hydrogen energy society such as the development of “hydrogen towns” and “hydrogen highways.” In addition, they are proactively engaged in activities to give glimpses of a hydrogen society to people, such as holding the “Kyu Uni Hydrogen Motor Show” at KYUSHU UNIVERSITY to provide opportunities to experience FCVs.

I strongly believe that research and development based on joint research with corporates will become more and more important. I believe that hydrogen will play a core role in sustainability not only in Japan but also in East Asia and the world.

STARLITE:UejimaI am reminded once again that we need to continue to develop our ALP piston rings in a hydrogen atmosphere as an indispensable product for the energy revolution towards the realization of a sustainable society. I promise that we will continue to make proposals that exceed society’s expectations with our tribology technologies. Thank you very much.