On Your Side Vol.5KYOCERA Document Solutions

KYOCERA Document Solutions × S-Bear GearThe “FUNCTION” developed by “CHALLENGE” with KYOCERA Document Solutions elevated Multifunction Printers (MFPs) to longer-lasting masterpieces and they are used beyond the office and in daily life.

A completely new material S-Bear was developed by the collaboration of KYOCERA and STARLITE. Its remarkable “durability and retentivity” played a major role in the completion of the MFPs, enabling it to have a long service life. We will be sharing our behind-the-scenes development story of highly durable S-Bear gear for the paper feeding drive unit.

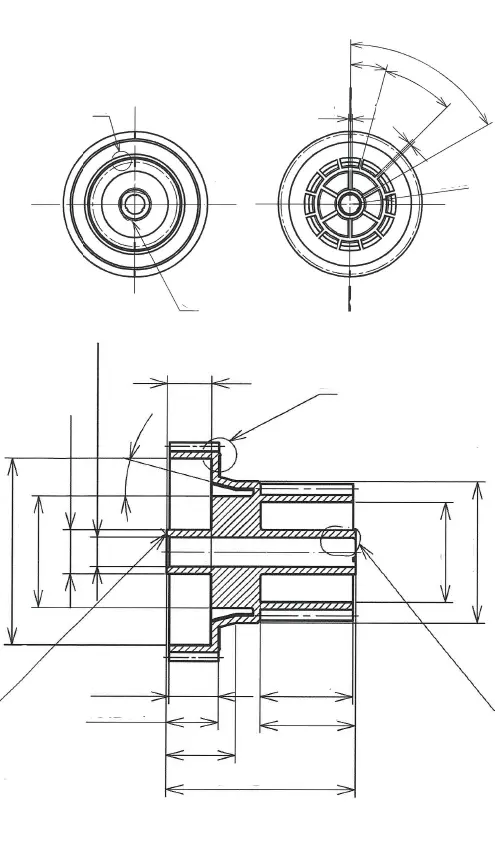

S-Bear Gear

"S-Bear Gear has not only stable sliding performance* but also lubrication-free performance, heat resistance and flame retardancy under severe operating conditions that exceeds 200 degree Celsus.

Operation continues with excellent sliding drive performance and high durability even in oil free environments such as robot joints, office equipment paper feeding drives, and automotive drive units.

S-Bear is a compound material whose functionality is pursued by shape design and performance evaluation and it is applied for gears, bearings, etc.

Sliding performance: easy to slide and its ability to slide"

On Your Side Vol.5 KYOCERA Document Solutions × STARLITEInterview with our customer

KYOCERA Document Solutions:Mr. Sakai“The key component of long-life MFPs is STARLITE’s S-Bear.”

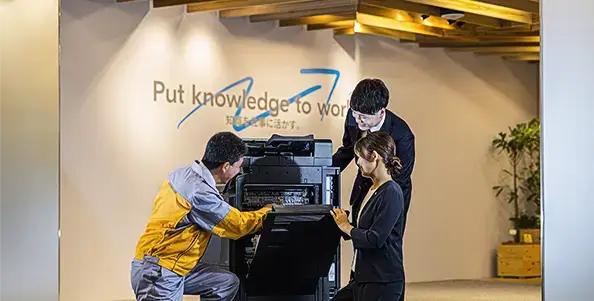

STARLITE:HiraokaI am very grateful for the interview opportunity here at “Knowledge Place Osaka” opened in April, 2021. You stated on your homepage that “Knowledge Place is a place to help people innovate something by combining knowldge and knowledge and create new value.” I am convinced this is exactly the space that is needed now.

I would like to thank you once again for using our “S-Bear” for many years.

I personally like the stylish design of the TASKalfa series. I get emotional when I think that our S-Bears are operating inside the MFP.

KYOCERA Document Solutions:Mrs. KikugawaThank you very much. Amid the demand for a sustainable society, our MFPs, based on the “long-life” product concept, are used in business and personal settings in more than 160 countries and regions around the world.

KYOCERA Document Solutions:Mr. SakaiAchieving “stable operation” was essential for the development of the “long-life” MFPs. However, we were not able to locate a dreamlike material that is highly durable and “wear- and tear-resistant…...” We were close to giving up at that time. However, it was STARLITE’s S-Bear that ticked all boxes. You managed to further improve the product to the level that lives up to its name, “long-life” MFPs. I would like to thank Hiraoka san and other STARLITE members once again.

KYOCERA Document Solutions:Mrs. Kikugawa“Our commitment to long-life products is what makes KYOCERA unique.”

STARLITE:HiraokaThat is undeserved honor. S-Bear is a completely new material that has high load capacity, excellent wear- and heat- resistance. This made it possible to provide “stable operation” in the drive unit, and we have been further improving the products for more than 30 years. Frankly speaking, when we were requested durability for printouts in excess of 1 million sheets, I was astonished, but I am pleased we were able to respond with our technology.

KYOCERA Document Solutions:Mrs. KikugawaI am sorry it was not an easy order :) However, our commitment to long-life products is what makes KYOCERA unique. We specialize in Fine Ceramics and that is what we are known for. We value our concept of “long-lasting use.” It was inevitable that we require “long life” for MFPs.

We are delighted that we have been able to release MFPs based on the long-life concept, which has been well received not only in Japan but also in other countries where environmental considerations are considered to be important. This has led to a positive reputation for our company for which we are very grateful.

STARLITE:HiraokaI am very pleased to hear that. Thinking back, it was a battle against “how long we will be able to keep durability.” Our highly durable “S-Bear” gear was a product that satisfied durability requirements even under an environment over 200 degrees Celsius, however, Kyocera’s dimensional specifications were so stringent that I remember we faced a lot of technical difficulties that we had to overcome in order to maintain the required performance.

In the end, STARLITE’s original material compounding and sliding test evaluation technologies enabled us to develop the optimum and highly durable sliding material for this application and meet your specifications.

“Long-lasting use” and “durability” are concepts for sustainability.

STARLITE:Hiraoka“We will contribute to future MFP evolution with new S-Bears.”

KYOCERA Document Solutions:Mr. SakaiWe always pursue the level we want, the level that satisfies our users. The difficulty here is that each customer has different criteria for “long-life.” In the business world, heavy use is required under a stable environment, and in people’s daily life, MFPs must be available “when needed.”

Continuous printing for long hours, use once every few days or weeks, printing under a high or low temperature... Humidity and dust... MFPs must operate steadily for a long period of time no matter under what conditions they are, otherwise, we will not be able to gain customers’ trust. It is our pride that we provide MFPs that can be used in any situation for a long time.

This is an episode in the aftermath of the Great East Japan Earthquake. We sent a number of MFPs which were used day and night. We were glad that we were able to support people who needed victim’s certificates and identity verification documents and we felt we had gained users’ trust.

STARLITE:HiraokaWe, STARLITE, also try to provide “functions for the betterment of society.” Therefore, I am glad we were able to support you. Long-life... yes, it was not simple.

We had to aim for long-life MFPs that generate heat due to heavy usage. This meant we have had to tackle various challenges such as temperature increase due to self-lubrication and friction on the paper feeding drive unit and other impacts from the heat source, etc.

I am developing a new “S-Bear” every time you develop a new model, however, there are challenges every time. I will keep providing various options based on numerous back data such as past data, friction and wear evaluation data, etc.

KYOCERA Document Solutions:Mrs. KikugawaI am very pleased. I am pleased that you are giving us various options, but what pleases me the most is that you are helping us by shortening the testing period on the actual machine. The cycle from analysis, development, Kaizen to test is very fast. I believe this is STARLITE’s Monozukuri.

S-Bear is the “material that can be used in a way we want.” I feel that it has more potential that exceeds our required specifications. This is the product that was born because you found solutions to all technical problems.

STARLITE:HiraokaThank you very much.By the way, Knowledge Place Osaka is so spacious. You can feel the greenery from the cafe next door and I feel that good and various ideas will keep coming up through relaxed conversations.

KYOCERA Document Solutions:Mr. SakaiYes, indeed. When I talk with a cup of coffee like this, a good idea comes to me out of the blue. It is often a good brainstorming, so I always have a memo in my hand. :) When you get an idea like that, it is often useful at work too. It makes me realize this is literally a circulation of knowledge.

The theme of the Knowledge Place is “Put knowledge to work,” but we also hope this place to be a space where ideas for various social issues are generated.

STARLITE:HiraokaWe will continue to manufacture products that will be used for even longer in order to realize a sustainable society. Please let us challenge to exceed your expectations with our tribology technologies*. Thank you very much for your time today.

*Tribology Technology: Tribology is “a science and technology that covers all phenomena that occur between two surfaces that affect each other while exerting relative motion,” including lubrication, friction, wear, seizure, and bearing design. From the science and technology of tribology, low friction, low wear and reduced surface damage of machines and parts are realized, which leads to energy saving and resource saving in our society.